Navigating Injection Molding Vendors in China

Well, the major meeting has just concluded. your new project has the green light, time is pressing, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. Savings can be substantial. Yet your thoughts are already spinning. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It feels like walking a thin line between big savings and total project failure.

However, here’s the reality. Sourcing China injection molding doesn’t have to be a gamble. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Forget the horror stories. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This becomes the bedrock of your sourcing project.

So, what goes in it?

Start with your 3D design files. They cannot be skipped. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the authoritative CAD geometry.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. This details critical info missing from the 3D file. Think tolerances, material grades, finish specs, and any feature-critical notes. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Don’t just say “Plastic.” Nor just “ABS.” Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. State your EAU. You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

Hunting for the Best Supplier

Now that your RFQ is pristine. who gets your RFQ? The web is vast but overwhelming. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Treat them as initial research tools, not final solutions. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Perhaps hire a local sourcing specialist. True, they charge a fee. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. As a newcomer, this offers priceless security. Think of it as insurance for your project timeline.

Another tactic: trade exhibitions. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. Plus, ask peers for referrals. Consult trusted colleagues. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

What’s the method? It blends technical checks with intuition.

First, look at their communication. Do they respond quickly and clearly? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It proves their expertise and involvement. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Request their machine list. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. You can’t skip this. Just as you interview hires, audit suppliers. You can travel or outsource a local inspector. They perform a one-day factory inspection. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

Once you’ve chosen your supplier. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

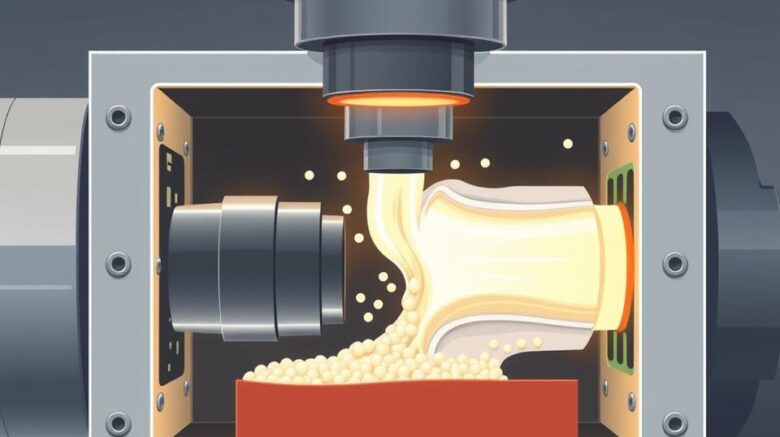

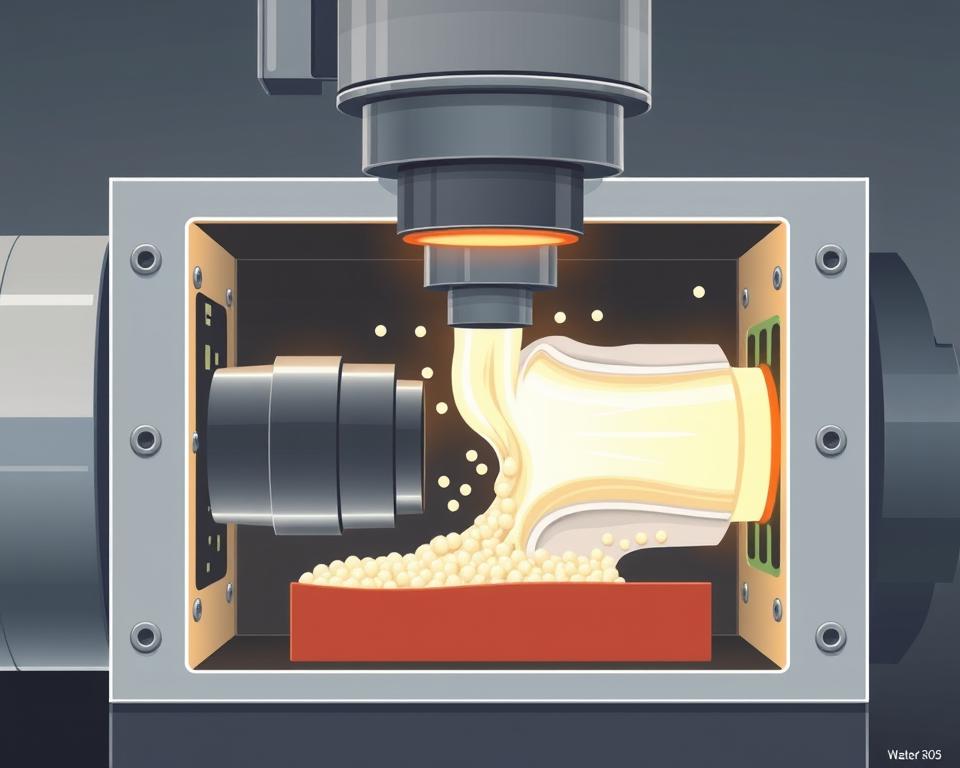

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. It’s their professional review of your CAD. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A thorough DFM is a sign of a professional operation. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These represent the first trial parts. It’s your test of success.

T1 parts usually require adjustments. That’s standard process. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You critique, they refine, and T2 plastic mold in China parts arrive. You may repeat this cycle a few times. Plan for this loop in your schedule.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Now comes full-scale production. How do you maintain consistency for part 10,000?

You need a clear Quality Control plan. Typically, this means a pre-shipment audit. Bring in an external QC firm. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They’ll send you a detailed report with photos and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Understand the shipping terms, or Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It hinges on strong supplier relations. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re ready.